What is Dyneema Made of?

Ultra-High-Molecular-Weight Polyethylene (UHMWPE)

Dyneema is a brand name for ultra-high-molecular-weight polyethylene (UHMWPE), which is a type of thermoplastic polymer. UHMWPE is made of extremely long chains of ethylene molecules, resulting in a lightweight, durable, and versatile material. The unique properties of Dyneema have led to its widespread use in various industries, including sports equipment, maritime, military, and aerospace applications.

Manufacturing Process

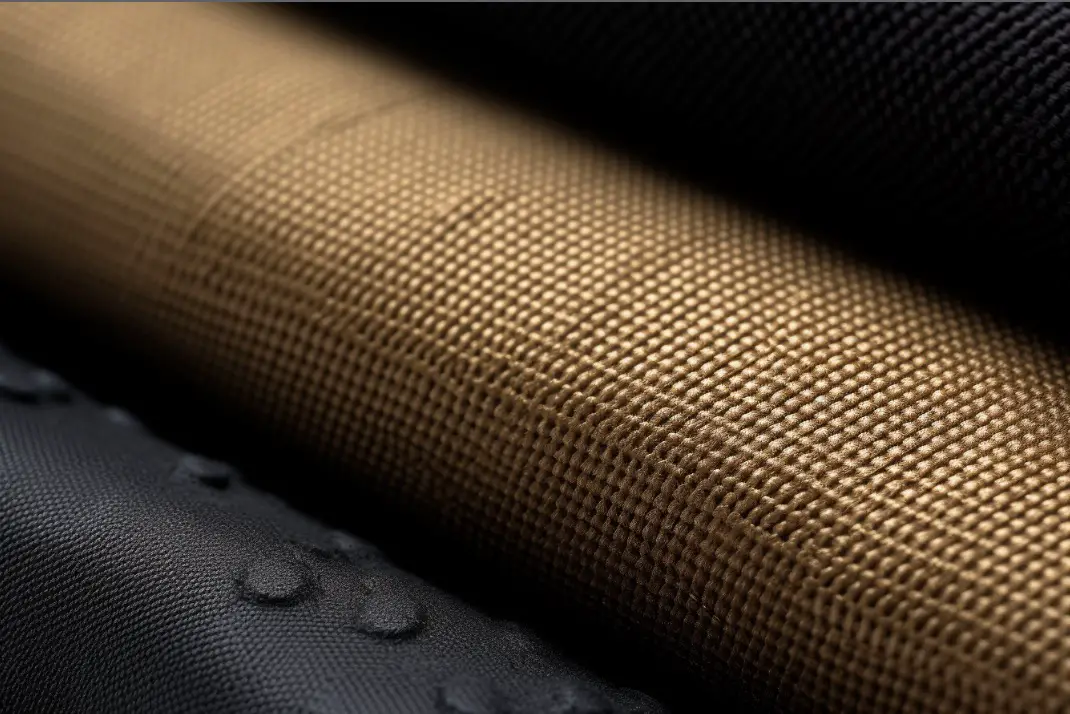

The manufacturing process of Dyneema begins with the polymerization of ethylene gas, which forms long chains of UHMWPE. These chains are then spun into fibers using a process called gel spinning. The fibers are drawn and aligned to create a strong, lightweight material with exceptional tensile strength. Finally, the fibers are woven or braided into ropes, fabrics, or other materials, depending on the intended application.

Unique Properties of Dyneema

High Strength-to-Weight Ratio

One of the most notable properties of Dyneema is its high strength-to-weight ratio. Dyneema is 15 times stronger than steel on a weight-for-weight basis, making it one of the strongest materials available. This property makes it an ideal choice for applications where strength and weight are critical factors, such as high-performance sports equipment, body armor, and mooring lines for ships.

Lightweight

Dyneema is incredibly lightweight, with a specific gravity of 0.97, which means it is lighter than water. This property makes it an excellent choice for applications where buoyancy is essential, such as marine ropes and nets.

Durability and Abrasion Resistance

Dyneema is highly resistant to abrasion, which is essential for applications where the material is subject to constant friction, such as ropes and slings. It also has excellent resistance to UV radiation and chemicals, making it suitable for outdoor and industrial applications.

Low Stretch

Dyneema has a low stretch characteristic, making it ideal for applications like rigging in sailing or lifting slings in industrial settings. This property ensures that the ropes and slings maintain their shape and strength even under heavy loads.

Water Resistance

Dyneema is hydrophobic, meaning it does not absorb water. This property makes it ideal for marine applications, as it does not become heavy when wet and maintains its strength and performance.

Applications of Dyneema

Sports Equipment

Dyneema is used in various sports equipment, such as kite lines, paragliding lines, and yacht rigging, due to its lightweight, high strength, and low stretch properties.

Body Armor and Ballistic Protection

Dyneema’s high strength-to-weight ratio and resistance to abrasion make it an ideal material for body armor and ballistic protection gear. It is used in bulletproof vests, helmets, and vehicle armor.

Maritime Industry

Dyneema ropes, nets, and slings are widely used in the maritime industry due to their lightweight, high strength, and water resistance properties. They are commonly used for mooring lines, towing lines, and lifting slings.

Aerospace and Aviation

Dyneema is used in various aerospace and aviation applications, such as cargo nets, parachute cords, and helicopter slings, due to its high strength, lightweight, and durability.

Industrial Applications

Dyneema’s unique properties make it suitable for a range of industrial applications, such as lifting slings, crane ropes, and protective gloves for workers handling sharp objects.

Conclusion

Dyneema is made of ultra-high-molecular-weight polyethylene (UHMWPE), a thermoplastic polymer with exceptional strength and durability. Here are ten key facts about Dyneema:

1.Dyneema is made of UHMWPE

2.It has a high strength-to-weight ratio

3.Dyneema is lightweight and buoyant

4.It is highly resistant to abrasion, chemicals, and UV radiation

5.Dyneema has low stretch properties

6.It is hydrophobic and water-resistant

7.Dyneema is used in sports equipment, such as kite lines and yacht rigging

8.It is an ideal material for body armor and ballistic protection

9.Dyneema ropes and nets are widely used in the maritime industry

10.It has various applications in aerospace, aviation, and industrial settings