If you’re in the market for a durable and versatile fabric, Cordura is a name you should know. In this article, we will explore the differences between Cordura 600D and 1000D, covering factors like weight, durability, water resistance, abrasion resistance, and cost.

1000D is the thicker fabric of the two, and therefore usually the more robust, wear and water proof but also the heaviest of the two.

We will also discuss the common uses for each type of Cordura, helping you determine which is better suited for your needs, whether it be for outdoor activities, military and tactical use, or everyday use. We will provide tips on how to properly care for your Cordura products to ensure they last for years to come.

So, whether you’re a seasoned adventurer or simply looking for a reliable everyday bag, read on to learn more about Cordura and make an informed decision.

What Is Cordura?

.jpg_00.jpeg)

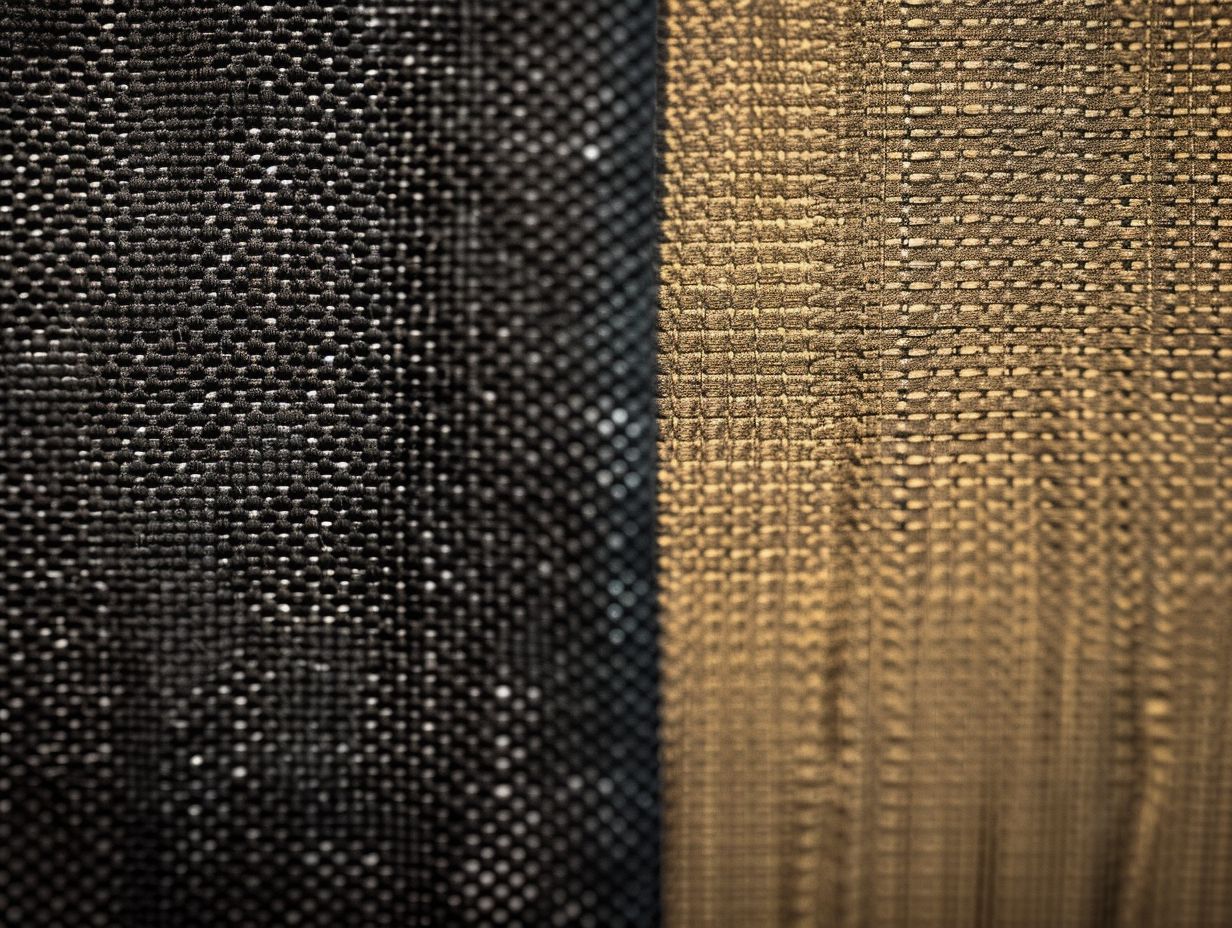

Cordura is a high-performance fabric known for its exceptional durability and strength, commonly used in the construction of various textiles and products. It is a type of nylon fabric that offers outstanding toughness and longevity compared to other synthetic materials.

Cordura fabric is composed of high-tenacity fiber, making it resistant to abrasions, tears, and scuffs. The manufacturing process involves weaving and coating the yarns to enhance its protective properties. This fabric’s versatility has led to its widespread use in industries such as military, outdoor gear, and tactical equipment.

Cordura’s unique selling points lie in its ability to withstand harsh conditions, making it ideal for backpacks, luggage, military uniforms, and motorcycle apparel. Its blend of durability, strength, and overall performance sets it apart as a top choice for heavy-duty applications.

What Are The Differences Between Cordura 600D And 1000D?

When comparing Cordura 600D and 1000D, the main variations lie in their denier count, which determines the weight, toughness, and specifications of the fabric. Understanding these differences is crucial for selecting the most suitable material for specific applications.

Cordura 600D is known for its lower denier count, offering a balance between durability and flexibility, making it ideal for applications requiring a lighter weight fabric with good abrasion resistance.

On the other hand, Cordura 1000D boasts a higher denier count, providing increased strength and ruggedness, making it perfect for heavy-duty applications that require exceptional toughness.

The weight-to-strength ratio of Cordura 600D makes it a preferred choice for items like backpacks, while the Cordura 1000D excels in products that need maximum durability, such as tactical gear and heavy-duty luggage.

Weight

The weight of Cordura 600D and 1000D fabrics plays a significant role in their performance and applications. Understanding how weight affects the overall resistance and specifications of these materials is essential for making informed decisions in selecting the right fabric for various uses.

The weight of Cordura fabrics directly impacts their durability and toughness. 600D and 1000D variants are specifically designed to withstand varying levels of stress and strain based on their weight.

For instance, a higher weight in the 1000D fabric results in increased abrasion resistance and tear strength, making it suitable for heavy-duty applications like military gear or backpacks. On the other hand, the lighter weight of 600D Cordura offers a balance between durability and flexibility, making it ideal for outdoor clothing and backpacks.

Therefore, considering weight as a determining factor is crucial to ensure that the fabric meets the specific requirements of the intended use.

Durability

Durability is a key factor distinguishing Cordura 600D and 1000D fabrics, with each variant offering specific advantages in terms of strength, toughness, and longevity. Understanding the durability of these materials is essential for assessing their performance in different environments and applications.

Cordura 600D is known for its excellent balance between durability and weight, making it a popular choice for a wide range of uses, from backpacks to motorcycle gear.

On the other hand, Cordura 1000D takes durability to the next level, providing exceptional strength and resistance to abrasions, punctures, and tears. The longevity of these fabrics is directly linked to their robust construction, ensuring they can withstand rigorous activities and harsh conditions without compromising performance.

This level of durability not only enhances the lifespan of products but also instills confidence in users relying on Cordura fabrics for their durability needs.

Water Resistance

Water resistance is a crucial feature to consider when comparing Cordura 600D and 1000D fabrics, as it determines their suitability for outdoor and tactical applications. Understanding the water resistance properties of these materials is essential for choosing the right fabric for specific uses.

Cordura 600D and 1000D fabrics are crafted with specialized coatings that create a barrier against moisture, ensuring that water beads up and rolls off the material rather than seeping through. This capability not only protects the fabric from getting saturated in rainy or wet conditions but also helps in maintaining the durability and integrity of the fabric over time.

Whether you are hiking through the rainforest or on a military mission in challenging terrains, having water-resistant fabrics like Cordura can be a game-changer, providing you with reliability and performance in varying weather scenarios.

Abrasion Resistance

Abrasion resistance is a critical factor that sets Cordura 600D and 1000D fabrics apart, showcasing their ability to withstand wear and tear in demanding environments. Understanding the abrasion resistance of these materials is essential for evaluating their quality and performance over time.

Cordura 600D and 1000D fabrics are specifically engineered to provide exceptional durability and resilience against friction-induced damage. Their high resistance to abrasion ensures that they maintain their structural integrity even after prolonged use in rugged conditions. This feature plays a key role in enhancing the overall lifespan of products made from these fabrics, making them ideal choices for applications that require long-lasting performance. The ability of Cordura fabrics to resist abrasion contributes significantly to their reputation for quality and reliability in various industries.

Cost

.jpg_01.jpeg)

Cost considerations play a vital role in choosing between Cordura 600D and 1000D fabrics, as the price difference can impact the overall value for specific applications. Understanding the cost implications is essential for weighing the pros and cons of each fabric variant.

When comparing Cordura 600D and 1000D fabrics, it’s evident that the 1000D variant is generally more expensive due to its higher denier count, making it a premium choice for applications requiring enhanced durability and strength. The 600D fabric, while more budget-friendly, offers favorable cost-effectiveness for applications where extreme ruggedness isn’t a primary concern.

Therefore, the decision between the two fabrics involves assessing the trade-off between cost and performance based on the specific needs of the intended use, ensuring that the chosen fabric aligns with both budgetary constraints and functional requirements.

What Are The Common Uses For Cordura 600D And 1000D?

Cordura 600D and 1000D fabrics find extensive applications in a variety of fields, including tactical gear, military equipment, outdoor gear, and luggage. Understanding the common uses of these fabrics is essential for selecting the most suitable material for specific requirements.

These fabrics are highly durable and resistant to abrasions, making them ideal for manufacturing heavy-duty backpacks, military uniforms, and protective gear. Cordura 600D is often used in backpacks and outdoor gear due to its balance of strength and weight, while Cordura 1000D, with its higher denier count, is favored for applications requiring even greater toughness, such as military gear and luggage. Both fabrics offer excellent water resistance, making them perfect for outdoor use in various weather conditions.

Cordura 600D

Cordura 600D is commonly employed in the production of tactical gear, backpacks, and outdoor gear due to its robustness and performance in rugged environments. Understanding the specific uses of Cordura 600D is crucial for leveraging its advantages in various applications.

This synthetic fabric is revered for its exceptional durability and resistance to abrasions, making it a top choice for those seeking gear that can withstand harsh conditions. Its ability to maintain strength and integrity even after prolonged use sets it apart in the world of outdoor equipment.

Whether it’s backpacks designed for long hiking trips or tactical gear requiring reliable performance during intense missions, Cordura 600D offers a balance of lightweight construction and heavy-duty protection. Its versatility extends to various color options, allowing for both functional design and aesthetic appeal in gear manufacturing.

Cordura 1000D

Cordura 1000D is favored in military and tactical applications for its unmatched strength-to-weight ratio and ballistic nylon properties. Understanding the specific uses of Cordura 1000D is essential for optimizing its performance in specialized equipment and gear.

This fabric’s exceptional durability and tear resistance make it ideal for manufacturing military backpacks, tactical vests, and rugged outdoor gear. The Cordura 1000D fabric can withstand harsh environments, abrasions, and heavy loads, ensuring reliable performance in demanding situations.

Its ability to maintain its structural integrity under stress enhances the longevity of gear, providing soldiers and outdoor enthusiasts with reliable equipment that can withstand the rigors of their missions. The fabric’s versatility extends to applications beyond military use, encompassing various industries that require top-tier performance and longevity in their equipment.

Which Is Better For My Needs?

Determining the ideal Cordura fabric for your specific needs depends on various factors such as intended use, environmental conditions, and required resistance levels. Understanding which variant aligns best with your requirements is essential for optimal performance.

- For outdoor activities that demand high abrasion resistance, choosing Cordura Ballistic is recommended due to its exceptional durability and tear strength.

- In contrast, for military applications necessitating a balance between weight and toughness, Cordura Classic might be more suitable.

- Consider Cordura HP fabric if you require enhanced waterproofing for use in wet or damp environments.

Each variant offers unique benefits, so evaluating your priorities and preferences will help you find the perfect Cordura fabric for your intended purpose.

Outdoor Activities

For outdoor activities, the choice between Cordura 600D and 1000D depends on the level of resistance, toughness, and longevity required for the gear or equipment. Understanding the specific needs of outdoor enthusiasts is essential for recommending the most suitable Cordura fabric.

While Cordura 600D offers a balance between durability and weight, making it ideal for backpacks and daypacks, the Cordura 1000D variant provides enhanced strength, suitable for heavy-duty backpacks, tactical gear, and items that undergo rigorous wear and tear.

The 600D fabric is well-suited for hiking trips and everyday use, offering good abrasion resistance and a lighter feel. On the other hand, the 1000D fabric excels in environments where extreme durability is crucial, such as military-grade equipment and heavy outdoor gear.”

Military And Tactical Use

.jpg_10.jpeg)

In military and tactical applications, the choice between Cordura 600D and 1000D is crucial for ensuring the necessary toughness, performance, and durability required in demanding scenarios. Understanding the specific needs of military and tactical professionals is essential for recommending the most suitable Cordura fabric.

The Cordura 600D variant, known for its balance of durability and lightweight construction, is favored for applications where agility and flexibility are key. This fabric offers excellent abrasion resistance, making it ideal for tactical gear that needs to withstand rugged environments.

On the other hand, Cordura 1000D, with its higher denier rating, provides superior strength and tear resistance, making it suitable for heavy-duty equipment and gear that may face intense wear and tear. Both options exhibit ballistic nylon properties, enhancing their ability to protect against punctures and tears, further solidifying their reliability for military and tactical use.

Everyday Use

For everyday applications, Cordura 600D and 1000D offer varying levels of performance and versatility, catering to different needs and preferences. Understanding how these fabrics align with everyday use cases is essential for recommending the most suitable Cordura variant.

- Cordura 600D, known for its balance of durability and flexibility, is often favored in products like backpacks, luggage, and outdoor gear that require a lighter weight yet resilient material.

- Conversely, Cordura 1000D, with its higher denier count, excels in applications that demand heavy-duty toughness, such as military gear, tool belts, and protective motorcycle clothing.

- The choice between the two largely depends on the intended use, where 600D suits everyday urban adventures, while 1000D shines in rugged environments where extreme durability is paramount.

How To Care For Cordura Products?

Proper care and maintenance are essential for prolonging the lifespan and performance of Cordura products. Understanding the correct cleaning, drying, and storage procedures is crucial for preserving the quality and durability of Cordura gear over time.

When it comes to cleaning Cordura items, it is recommended to hand wash them using a mild detergent and cold water. Avoid using harsh chemicals or bleach as they can damage the fabric. After washing, gently blot excess water with a towel and let the item air dry completely.

When storing Cordura gear, ensure it is clean and completely dry to prevent mold or mildew growth. Store items in a cool, dry area away from direct sunlight to maintain their color and integrity.

Cleaning

Cleaning Cordura products requires specific care to ensure the fabric’s longevity and performance. Understanding the proper cleaning techniques and maintenance routines is essential for preserving the quality of Cordura gear over time.

Regular maintenance of Cordura items not only enhances their durability but also retains their appearance. To clean Cordura gear effectively, start by removing any loose dirt or debris with a gentle brush or damp cloth. For tougher stains, use a mild detergent or specialized fabric cleaner recommended for Cordura. Gently scrub the affected areas and rinse thoroughly with lukewarm water. Avoid using harsh chemicals, bleach, or high heat when cleaning Cordura, as these can damage the fabric. Hang the gear to air dry completely before storing to prevent mildew or odors.

Drying

Proper drying techniques are essential for maintaining the quality and durability of Cordura products after cleaning. Understanding the correct drying methods and precautions is crucial for ensuring the longevity and performance of Cordura gear.

It is recommended to air dry Cordura products in a well-ventilated area away from direct sunlight or heat sources to prevent damage to the fabric. Hanging the items on a line or laying them flat on a clean surface can help maintain their shape and integrity during the drying process. Avoid using a dryer as the high heat can potentially shrink or weaken the Cordura material. By following these proper drying practices, you can prolong the life of your Cordura gear and retain its quality for your outdoor adventures.

Storage

Proper storage is crucial for protecting Cordura products from damage and preserving their quality during periods of non-use. Understanding the best practices for storing Cordura gear ensures long-lasting durability and performance.

When storing Cordura products, it is recommended to clean them thoroughly before packing them away. Any dirt, grime, or stains left on the fabric can lead to discoloration and deterioration over time. Ensure that the items are completely dry to prevent mold and mildew growth. It is advisable to store Cordura gear in a cool, dry place away from direct sunlight and moisture. Avoid folding the items for extended periods to prevent creases or wrinkles in the fabric. By following these maintenance guidelines, you can extend the lifespan of your Cordura products and maintain their optimal performance.

Frequently Asked Questions

.jpg_11.jpeg)

What is the difference between Cordura 600D and 1000D?

Cordura 600D and 1000D are both types of fabric commonly used in outdoor and military gear. The main difference between them is the denier count, with 600D having a lower denier count than 1000D.

What does denier count mean?

Denier count is a unit of measurement used to determine the thickness or weight of a fabric. It refers to the mass in grams of a 9000-meter length of yarn. The higher the denier count, the thicker and heavier the fabric will be.

Which one is stronger, Cordura 600D or 1000D?

In terms of strength, 1000D is stronger than 600D due to its higher denier count. This means it can withstand more wear and tear, making it a better choice for heavy-duty or high-impact use.

Is one more durable than the other?

While 1000D is considered to be more durable than 600D, both fabrics have high durability and are commonly used in outdoor and military applications. The durability of the fabric also depends on other factors such as the weaving pattern and finish.

What are the advantages of using Cordura 600D over 1000D?

One advantage of using Cordura 600D is that it is lighter and more flexible than 1000D, making it a better choice for applications where weight and mobility are important. It is also more affordable than 1000D, making it a popular choice for budget-conscious consumers.

In what situations would I choose Cordura 1000D over 600D?

If you are looking for a fabric that can withstand heavy use or extreme conditions, Cordura 1000D would be the better option. It is also recommended for applications where weight is not a major consideration, such as heavy-duty backpacks or tactical gear.