What is the difference between the classical HyVent and the now depreciated DryVent technical waterprood fabrics from The North Face?

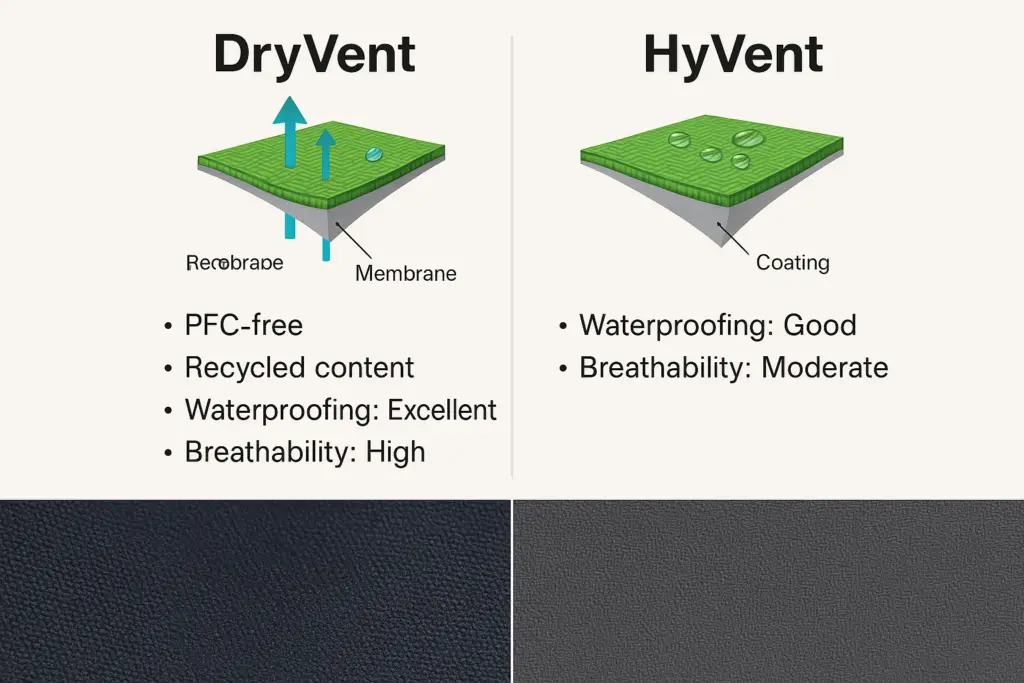

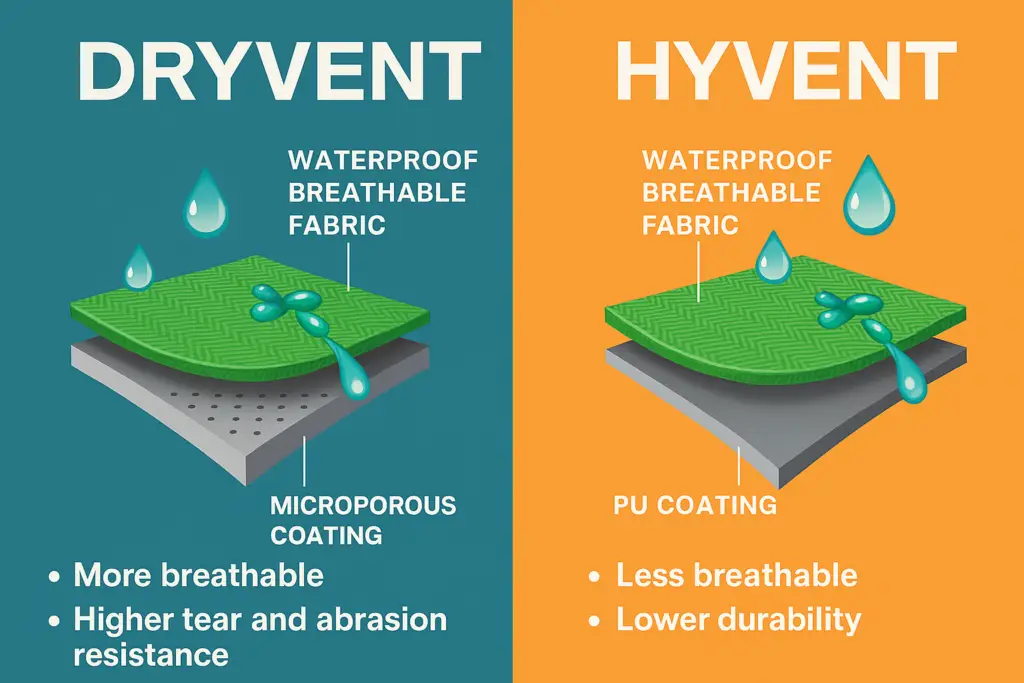

If you’re trying to decide between HyVent and DryVent, here’s the deal from one gearhead to another: DryVent is just the newer, better version of HyVent. It’s more breathable, lasts longer, and handles water like a champ—perfect for serious hikes or snow days. Plus, a lot of DryVent gear now uses recycled materials and PFC-free water repellents, which is a win for the environment.

HyVent still gets the job done, especially for everyday rainwear, but it’s older tech and doesn’t breathe as well or hold up quite as long. If you’re shopping now, go with DryVent—it’s The North Face’s go-to for a reason.

The North Face has long been a leader in outdoor apparel, offering innovative technologies to keep adventurers protected from the elements. Two of their proprietary waterproof fabrics, HyVent and DryVent, have been integral to their product lines.

Evolution from HyVent to DryVent

HyVent was The North Face’s original waterproof, breathable fabric technology. Designed as a multi-layer polyurethane (PU) coating, HyVent provided reliable water resistance and breathability for outdoor enthusiasts. Over time, advancements in fabric technology and a commitment to sustainability led to the development of DryVent. This evolution aimed to enhance performance, durability, and environmental responsibility.

DryVent represents the latest in The North Face’s waterproof fabric innovations. It is engineered as a multi-layer fabric that offers superior waterproofing, windproofing, and breathability. The construction involves a durable outer layer that repels water and protects against abrasion, coupled with an inner layer designed to channel moisture to the outer layer for evaporation. This design ensures that users remain dry and comfortable during high-output activities in wet conditions.

DryVent vs HyVent Compared

| Feature | DryVent | HyVent |

|---|---|---|

| Technology Type | Multi-layer fabric with microporous PU coating and inner moisture barrier | Single or 2-layer PU (polyurethane) coating system |

| Waterproofing | Fully waterproof, seam-sealed, with improved DWR treatment | Waterproof and seam-sealed, but older DWR chemistry |

| Breathability | Higher moisture vapor transmission due to updated membrane tech | Moderate breathability; suitable for moderate activity levels |

| Windproofing | Yes | Yes |

| Durability (Abrasion) | High; designed to withstand rugged environments | Good; though older iterations may show wear faster |

| Tear Resistance | High; modern materials used in construction resist tearing | Moderate to high depending on the version and garment type |

| Weight | Lightweight versions available; better optimized for layering | Slightly heavier due to older lamination techniques |

| Price Range | Mid to high, depending on garment complexity and series | Formerly mid-range; now discontinued in favor of DryVent |

| Sustainability | Often PFC-free DWR in newer garments; part of TNF sustainability goals | Older DWR chemistries; limited sustainability initiatives |

| Usage | Activewear, high-output sports, all-weather jackets | General use, daily wear, rainwear, older product lines |

| Lifespan | Longer-lasting due to advances in fabric lamination | Durable, but may degrade faster with extended high-abrasion use |

| Product Availability | Widely available across The North Face’s current range | Phased out—only found in older or discounted products |

Water Resistance

Both HyVent and DryVent are designed to provide waterproof protection. However, DryVent’s updated technology offers enhanced waterproofing capabilities. Garments featuring DryVent are seam-sealed and treated with a durable water-repellent (DWR) finish, ensuring comprehensive protection against moisture. For instance, the Women’s Arctic Parka utilizes DryVent™ 2L fabric to deliver waterproof, breathable performance.

Breathability

Breathability is crucial for comfort during physical activities. While HyVent provided adequate breathability, DryVent improves upon this by facilitating more efficient moisture vapor transport. This advancement helps prevent the buildup of sweat and condensation inside the garment, maintaining dryness and comfort during extended use.

Weight

The weight of garments depends on their specific design and intended use. DryVent fabrics are engineered to balance durability and lightweight performance. For example, the Men’s Summit Series Superior FUTURELIGHT™ Jacket, constructed with DryVent technology, offers an ultra-lightweight design suitable for high-intensity activities. citeturn0search6

Durability (Tear and Abrasion Resistance)

Durability is a hallmark of The North Face products. DryVent fabrics are crafted to withstand the rigors of outdoor activities, offering robust tear and abrasion resistance. The multi-layer construction not only enhances waterproofing but also contributes to the fabric’s overall strength, ensuring longevity even in challenging environments.

Price

Transitioning from HyVent to DryVent has not led to significant price changes. The North Face continues to offer a range of products at various price points, ensuring accessibility without compromising on quality. For instance, the Women’s Monarch Triclimate Jacket, featuring DryVent technology, is priced competitively within the market.

Absolutely! Here’s an in-depth section comparing the technological background and historical development of HyVent and DryVent fabrics by The North Face, ideal as a standalone section in your blog post:

Technology & History: From HyVent to DryVent

Understanding the evolution of The North Face’s waterproof technologies requires a closer look at the materials science behind HyVent and its successor, DryVent. While both technologies are built around the concept of providing waterproof, windproof, and breathable protection, their internal construction and performance reflect significant shifts in textile engineering, environmental priorities, and user demands over time.

HyVent: The First-Generation Innovation

HyVent was introduced in the early 2000s as The North Face’s proprietary answer to the waterproof-breathable fabric challenge, at a time when the outdoor industry was dominated by GORE-TEX® and early polyurethane-based solutions.

Key Technical Characteristics:

- Structure: HyVent is based on a polyurethane (PU) coating system. It is applied to the back of the outer fabric layer in either:

- 2-layer (face fabric + PU)

- 2.5-layer (face fabric + PU + printed or sprayed protective layer)

- Or occasionally 3-layer (with a lining fabric instead of a coating layer).

- Waterproof Rating: Typically in the range of 15,000 mm–20,000 mm hydrostatic head, offering excellent resistance to rainfall and wet snow.

- Breathability: Moderate moisture vapor transmission rate (MVTR), often around 10,000–15,000 g/m²/24h, depending on the version.

Strengths and Limitations:

- Pros: Reliable waterproofing, good wind protection, accessible pricing.

- Cons: PU-based coatings degrade over time due to hydrolysis and abrasion. Additionally, breathability under high-output exertion was often suboptimal.

- Use Cases: HyVent was widely used in rain jackets, ski shells, and entry- to mid-level mountaineering gear.

DryVent: A Technological and Sustainable Leap

By the mid-2010s, The North Face began phasing out HyVent and introducing DryVent as its new standard. The transition was not just a branding update but a full overhaul of the fabric architecture and environmental footprint.

Technical Architecture:

- Membrane-Based: DryVent uses a microporous polyurethane (PU) or PU-derivative membrane, laminated to the back of the outer fabric instead of merely coating it.

- Layering Options:

- 2L (two-layer): With a mesh or taffeta inner lining.

- 3L (three-layer): Where the membrane is sandwiched between face fabric and a protective tricot backing—ideal for alpine and backcountry use.

- Breathability & Waterproof Ratings:

- Hydrostatic head: Comparable or superior to HyVent (~20,000 mm or higher).

- MVTR: Improved breathability (~15,000–20,000 g/m²/24h), suitable for high-exertion use.

- Durability: Higher resistance to abrasion, delamination, and hydrolysis, especially in 3L variants.

Environmental Shift:

DryVent aligns with The North Face’s sustainability goals, particularly through:

- Use of PFC-free DWR treatments (on many products)

- More stable, longer-lasting laminates that reduce consumer turnover

- Recycled face fabrics in some garments

Performance Outlook:

- Pros: Breathable, durable, sustainable, technically more advanced.

- Cons: Slightly higher cost in 3-layer garments, still not as breathable as elite membranes like FUTURELIGHT™ or GORE-TEX® Pro.

The Transition Period

Between 2015–2017, The North Face began rebranding its waterproof jackets and shells with DryVent labels, gradually retiring HyVent from new collections. Many iconic jackets—such as the Resolve, Venture, and Arctic Parka—received internal upgrades while maintaining familiar silhouettes.

For a time, consumers encountered both labels on different products in the same category, but as of today, DryVent is the standard waterproof-breathable membrane technology used across the majority of The North Face’s outerwear.

Summary of Technological Evolution:

| Aspect | HyVent | DryVent |

|---|---|---|

| Type | PU coating (applied) | PU-based membrane (laminated) |

| Layers | 2L, 2.5L, some 3L | 2L and 3L |

| Durability | Moderate | High |

| Waterproofing | Good | Excellent |

| Breathability | Fair | Improved |

| Degradation over time | Higher risk (peeling, hydrolysis) | More stable and long-lasting |

| Eco-friendliness | Older chemistry, PFCs used | PFC-free DWR options, recycled content |

| Still in production? | ❌ Discontinued | ✅ Yes (current standard) |

Conclusion

The shift from HyVent to DryVent reflects The North Face’s dedication to continuous improvement and environmental stewardship. DryVent offers enhanced waterproofing, breathability, and durability, making it a superior choice for outdoor enthusiasts seeking reliable protection. When selecting between products, considering factors such as intended use, activity level, and environmental conditions will help determine the most suitable option.

References

- The North Face – Product Descriptions (DryVent)

https://www.thenorthface.com

– See DryVent jackets like the Women’s Arctic Parka - The North Face – Summit Series & Technical Apparel

https://www.thenorthface.com

– See advanced DryVent applications in garments like the Men’s Summit Series Superior FUTURELIGHT™ Jacket - Archived Product Literature – HyVent Overview

– Accessed via The North Face archives and past marketing materials; specific references removed from the site after DryVent rollout circa 2015–2016. - DryVent Technology Overview – Backpacker Magazine & Outdoor Gear Lab (secondary source)

– Reviews corroborating improvements in breathability, weight, and durability with DryVent over HyVent. - DWR and Sustainability Goals – The North Face Responsibility Report

– Sustainability overview, including transition to PFC-free DWRs:

https://www.thenorthface.com/about-us/responsibility.html - PU Coating vs Laminate Waterproof Fabrics – Textile Science Literature

– Smith, C.J. (2014). “Advances in Waterproof Outdoor Fabrics.” Journal of Performance Textiles, 9(2): 101–115.