600D nylon is a widely used synthetic fabric known for its durability, strength, and versatility. It has become a popular material in various industries due to its exceptional performance and affordability.

In this article, we will delve into the definition of 600D nylon, explore its manufacturing process, discuss its key characteristics, examine its common uses, compare it with other materials, provide care and maintenance tips, and address its environmental impact.

Understanding the Basics of 600D Nylon

When it comes to choosing the right fabric for various applications, understanding the different types of materials available is crucial. One such fabric that is widely used is 600D nylon. Let’s delve deeper into what 600D nylon is and how it is manufactured.

Definition of 600D Nylon

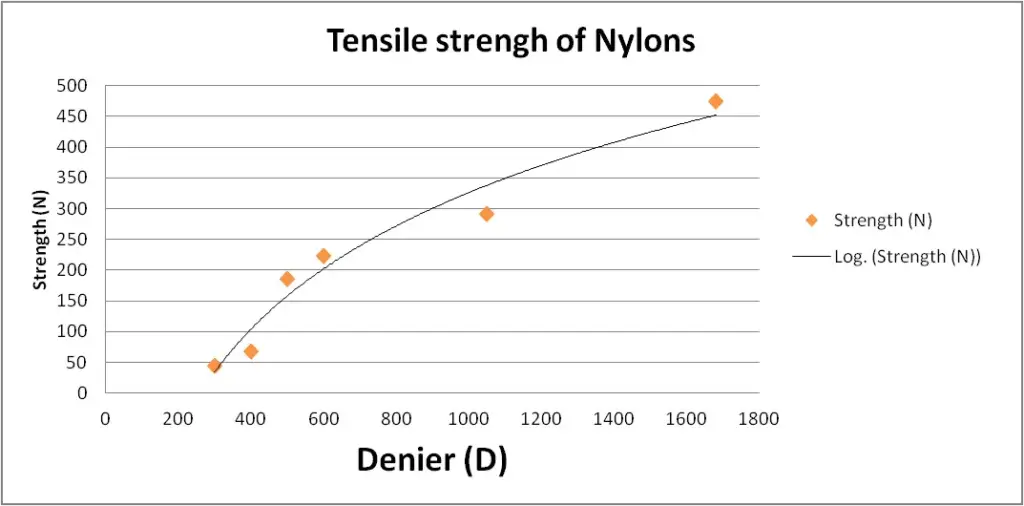

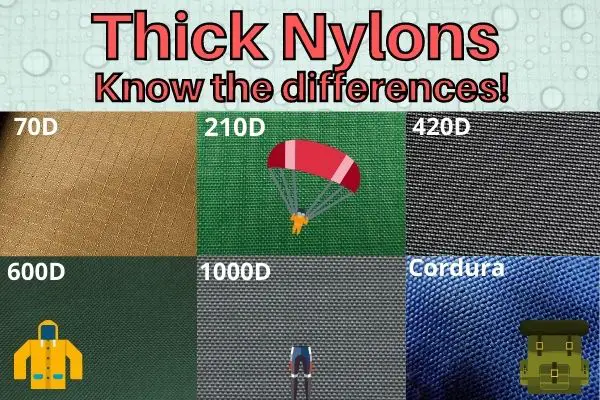

600D nylon is a type of fabric that belongs to the family of nylon materials. The “600D” in its name refers to the fabric’s denier count. Denier is a unit of measurement for the linear mass density of fibers. In simple terms, the denier count indicates the thickness and strength of the fabric. A higher denier count signifies a stronger and more durable material.

With a denier count of 600, this nylon fabric is known for its exceptional strength and durability. It is commonly used in the production of bags, backpacks, luggage, and other heavy-duty applications where sturdiness is essential.

The Manufacturing Process of 600D Nylon

The manufacturing process of 600D nylon involves several intricate steps to create a fabric that meets the desired specifications. Let’s take a closer look at how this fabric is made.

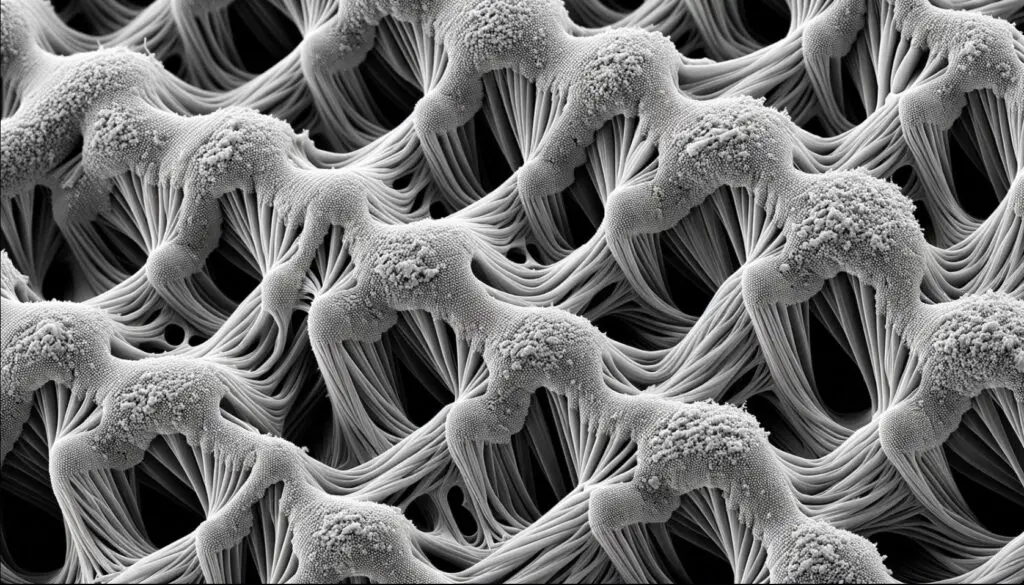

The process begins with the selection of high-quality nylon polymer, which is derived from petrochemicals. This polymer is then melted and extruded into long filaments. These filaments are incredibly thin, measuring only a fraction of a millimeter in diameter.

Once the filaments are extruded, they are spun into yarns. This spinning process helps to align the filaments, making them stronger and more cohesive. The resulting yarns are then ready to be woven into fabric.

Various weaving techniques are employed to create a fabric with a tight and durable structure. These techniques include plain weave, twill weave, and satin weave, among others. The choice of weaving technique depends on the desired characteristics of the final fabric.

After the fabric is woven, it undergoes a finishing process to enhance its performance. One common finishing technique is the application of a water-resistant or waterproof coating. This coating helps to repel water and protect the fabric from moisture damage, making it ideal for outdoor applications.

600D nylon fabric is known for its excellent abrasion resistance, tear strength, and overall durability. It can withstand heavy loads and harsh environmental conditions, making it a popular choice in industries such as camping, hiking, and military gear.

Furthermore, this fabric is available in a wide range of colors and patterns, allowing for creative and aesthetically pleasing designs. Whether you’re looking for a vibrant and eye-catching backpack or a sleek and professional-looking laptop bag, 600D nylon offers versatility in both functionality and style.

In conclusion, 600D nylon is a robust and reliable fabric that offers exceptional strength and durability. Its manufacturing process involves the careful selection of high-quality nylon polymer, extrusion of filaments, spinning into yarns, weaving, and finishing. With its water-resistant properties and wide range of applications, 600D nylon is a go-to choice for many industries.

Key Characteristics of 600D Nylon

When it comes to choosing the right material for your products, durability and strength are two important factors to consider. Luckily, 600D nylon excels in both areas, making it a popular choice for a wide range of applications.

Durability and Strength

One of the standout features of 600D nylon is its exceptional durability and strength. With a high denier count, this fabric is designed to withstand heavy use and resist tears. Whether you’re manufacturing backpacks, luggage, or outdoor gear, 600D nylon offers excellent durability that will ensure your products last for a long time.

But what exactly is denier? Denier is a unit of measurement that refers to the linear mass density of fibers. In simpler terms, it measures the thickness and weight of the fabric. The higher the denier count, the stronger and more durable the material.

Water and Abrasion Resistance

Aside from its durability, 600D nylon also possesses excellent water and abrasion resistance properties. The tight weave structure and the presence of a protective coating make it highly resistant to water penetration.

| Metric | Description | Influence on Water Resistance |

|---|---|---|

| Weave | Tightness of the fabric’s weave | Tighter = More resistant |

| Denier | Thickness of individual fibers in the fabric | Higher = More resistant |

| Tex | Another measure of fiber thickness | Higher = More resistant |

This means that even in wet conditions, the contents of bags, tents, and other products made from 600D nylon will remain dry and protected.

Furthermore, its resistance to abrasion ensures that it can withstand frequent use without showing signs of wear and tear. This is particularly important for products that are exposed to rough environments or constant friction, such as backpacks that are constantly being carried around or outdoor gear that is subjected to various outdoor elements.

Lightweight and Flexibility

Despite its exceptional strength and durability, 600D nylon remains relatively lightweight. This makes it an ideal choice for applications that require portability and ease of use. Whether you’re designing a lightweight backpack for hiking or a compact tent for camping, 600D nylon will provide the necessary strength without adding unnecessary weight.

Additionally, the fabric’s flexibility allows it to conform to different shapes and structures. This means that products made from 600D nylon can adapt to various designs, ensuring a perfect fit and functionality. Whether you’re creating a backpack with multiple compartments or a tent with unique shapes, 600D nylon will provide the flexibility needed to bring your designs to life.

In conclusion, 600D nylon is a versatile and reliable material that offers exceptional durability, water and abrasion resistance, as well as lightweight and flexibility. Whether you’re a manufacturer or a consumer, understanding the key characteristics of 600D nylon will help you make informed decisions when it comes to choosing the right material for your products.

Common Uses of 600D Nylon

600D nylon is a versatile and widely used fabric that finds applications in various industries. Its combination of durability, water resistance, and lightweight properties make it a popular choice for many different products.

Outdoor Gear and Equipment

One of the most common uses of 600D nylon is in the manufacturing of outdoor gear and equipment. Backpacks, duffel bags, and tents often utilize this fabric due to its exceptional strength and ability to withstand rugged outdoor conditions. Whether you’re embarking on a hiking expedition or going camping, gear made from 600D nylon provides the necessary durability and water resistance to keep your belongings safe and dry.

But it doesn’t stop there. Even outdoor furniture such as camping chairs and hammocks frequently feature 600D nylon. The fabric’s robust nature ensures that these furniture pieces can withstand the elements and provide comfort and stability for outdoor relaxation.

Clothing and Accessories

600D nylon is not limited to outdoor gear; it has also made its way into the world of clothing and accessories. Jackets, pants, and bags made from this fabric offer wearers protection against harsh weather conditions. Whether you’re hiking in the mountains or exploring a rainforest, clothing made from 600D nylon provides a reliable barrier against wind, rain, and other elements.

Moreover, the durability of 600D nylon makes it an ideal choice for professionals and outdoor enthusiasts who require gear that can withstand rigorous use. From backpacks to utility belts, this fabric ensures that your gear remains intact and functional, no matter the adventure.

Furniture and Upholstery

Due to its strength and resistance to abrasion, 600D nylon is sometimes used in the upholstery of furniture. It provides a durable and easy-to-clean surface that can withstand significant wear and tear. Whether it’s a sofa, chair, or even a car seat, 600D nylon upholstery offers a long-lasting solution that can handle everyday use.

Additionally, the water resistance of 600D nylon makes it suitable for outdoor furniture. Patio chairs, lounge sets, and other outdoor pieces can benefit from the fabric’s ability to repel water and resist fading caused by prolonged exposure to the sun.

Overall, 600D nylon is a versatile fabric that finds its place in various industries. Its durability, water resistance, and lightweight properties make it an excellent choice for outdoor gear, clothing, accessories, and even furniture upholstery.

Comparing 600D Nylon with Other Materials

When it comes to choosing the right fabric for your needs, it’s important to consider the specific characteristics and qualities of each material. In this comparison, we will explore how 600D nylon stacks up against polyester, leather, and canvas.

600D Nylon vs. Polyester

Both 600D nylon and polyester are popular choices for various applications due to their strength and durability. However, there are some key differences between the two. While both fabrics offer similar levels of strength, 600D nylon tends to be slightly stronger and more resistant to tearing. This makes it an excellent choice for heavy-duty applications such as backpacks, luggage, and outdoor gear.

On the other hand, polyester excels in terms of moisture wicking. It has the ability to quickly draw moisture away from the body, making it a popular choice for activewear and sportswear. Polyester is also known for its lightweight and quick-drying properties, making it ideal for outdoor activities and athletic pursuits.

600D Nylon vs. Leather

When it comes to durability and strength, leather surpasses 600D nylon. Leather is a natural material that can withstand heavy use and age beautifully over time. It is known for its luxurious look and feel, making it a popular choice for high-end products such as handbags, shoes, and furniture.

However, 600D nylon has its own advantages over leather. One of the key benefits of 600D nylon is its water resistance. Unlike leather, which can be damaged by water and requires special care, 600D nylon is highly resistant to water. This makes it a great choice for outdoor gear, rain jackets, and other items that need to withstand wet conditions.

Another advantage of 600D nylon over leather is its affordability. Leather products tend to be more expensive due to the cost of sourcing and processing the material. 600D nylon, on the other hand, is a synthetic fabric that is more readily available and cost-effective, making it a popular choice for budget-conscious consumers.

Additionally, 600D nylon is easier to maintain and clean compared to leather. While leather requires special cleaning products and regular conditioning to keep it in good condition, 600D nylon can be easily wiped clean with a damp cloth or washed in a machine, making it a practical choice for everyday use.

600D Nylon vs. Canvas

Canvas is another commonly used fabric that is often compared to 600D nylon. Both materials possess excellent durability and abrasion resistance, making them suitable for a wide range of applications.

However, there are some notable differences between 600D nylon and canvas. One of the key advantages of 600D nylon over canvas is its water resistance. While canvas can absorb water and become heavy and soggy, 600D nylon is highly resistant to water, making it ideal for outdoor gear, backpacks, and tents.

Another advantage of 600D nylon is its lightweight properties. Compared to canvas, which can be quite heavy and bulky, 600D nylon offers a lightweight alternative without compromising on strength and durability. This makes it a popular choice for travel bags, backpacks, and other items where weight is a consideration.

On the other hand, canvas is known for its breathability and natural feel. It is often used in applications where breathability is important, such as tents, shoes, and clothing. Canvas also has a unique texture and appearance that some people find appealing, giving it a timeless and classic appeal.

In conclusion, when comparing 600D nylon with other materials such as polyester, leather, and canvas, it’s important to consider the specific needs and requirements of your project. Each material has its own unique characteristics and advantages, and choosing the right one will depend on factors such as strength, durability, water resistance, breathability, and cost.

Care and Maintenance of 600D Nylon Products

When it comes to caring for your 600D nylon products, proper cleaning and maintenance are essential to ensure their longevity and performance. In this guide, we will provide you with detailed instructions on how to clean and care for your 600D nylon products, as well as some useful tips to help you make the most out of them.

Cleaning Instructions

To clean your 600D nylon products, it is important to follow the proper cleaning procedures to avoid damaging the fabric. Start by gently scrubbing the surface using a soft brush or sponge and mild soap or detergent. Make sure to use warm water, as hot water can cause the fabric to shrink or lose its shape.

Avoid using harsh chemicals or abrasive cleaners, as they can strip away the fabric’s protective coating and compromise its durability. Instead, opt for mild soap or detergent that is specifically formulated for delicate fabrics. This will help to remove dirt, stains, and odors without causing any harm to the fabric.

After cleaning, rinse the product thoroughly with clean water to remove any soap residue. It is important to remove all traces of soap, as leftover residue can attract dirt and make the fabric look dull. Once rinsed, gently squeeze out any excess water and allow the product to air dry completely before storing or using it again.

Tips for Longevity

While proper cleaning is crucial, there are also other measures you can take to extend the lifespan of your 600D nylon products. Here are some useful tips to help you maintain their quality and performance:

- Avoid overloading: It is important to use your 600D nylon products within their intended capacity. Overloading them with excessive weight or strain can weaken the fabric and lead to premature failure. Be mindful of the weight limits specified by the manufacturer and avoid exceeding them.

- Store in a cool and dry environment: When your 600D nylon products are not in use, it is advisable to store them in a cool and dry environment. Moisture can promote the growth of mold and mildew, which can not only damage the fabric but also create an unpleasant odor. To prevent this, ensure that your products are completely dry before storing them and keep them in a well-ventilated area.

- Avoid prolonged exposure to sunlight: While 600D nylon is known for its durability, prolonged exposure to sunlight can cause the fabric to fade and weaken over time. If possible, store your products in a shaded area or use protective covers to shield them from direct sunlight when not in use.

By following these care and maintenance tips, you can ensure that your 600D nylon products remain in excellent condition for years to come. Remember, proper care and attention will not only prolong their lifespan but also enhance their performance and appearance.

Environmental Impact of 600D Nylon

Sustainability Concerns

As a synthetic material derived from petrochemicals, 600D nylon raises sustainability concerns. The production of nylon involves the consumption of non-renewable resources and the emission of greenhouse gases.

The extraction and processing of petroleum, the primary raw material for nylon production, can have detrimental effects on the environment. Additionally, the energy-intensive manufacturing process of nylon contributes to carbon dioxide emissions, further exacerbating climate change.

Furthermore, the production of nylon involves the use of various chemicals, such as adipic acid and hexamethylenediamine, which can have negative impacts on ecosystems and human health. These chemicals may be released into the environment during the manufacturing process or when nylon products are disposed of improperly.

However, advancements in recycling technology and the use of bio-based alternatives are being explored to minimize the environmental impact of nylon. Researchers are investigating methods to improve the efficiency of nylon recycling processes, aiming to reduce the need for virgin nylon production and decrease waste generation. Moreover, the development of bio-based nylon, derived from renewable resources such as plant-based materials, offers a promising alternative to traditional petrochemical-based nylon.

Recycling and Disposal Options

Currently, there are limited recycling options available for 600D nylon. However, as awareness about recycling and circular economy initiatives grows, efforts are being made to develop recycling processes for nylon fabrics. These processes involve the collection, sorting, and reprocessing of nylon waste into new materials or products. By implementing effective recycling systems, the environmental impact of nylon can be significantly reduced.

When disposing of 600D nylon products, it is recommended to follow local waste management guidelines and ensure they are sent to appropriate recycling facilities. This helps prevent the accumulation of nylon waste in landfills, where it can take hundreds of years to decompose. Proper disposal and recycling of nylon products contribute to the conservation of resources and the reduction of greenhouse gas emissions.

Moreover, innovative approaches such as upcycling and repurposing can extend the lifespan of 600D nylon products. By finding new uses for old or worn-out nylon items, we can reduce the demand for new nylon production and minimize waste generation.

In conclusion, 600D nylon is a versatile fabric that offers exceptional durability, water resistance, and flexibility. It finds applications in various industries, including outdoor gear, clothing, and upholstery. While it has its environmental concerns, efforts are being made to address them.

By understanding the properties and characteristics of 600D nylon, consumers can make informed choices about its usage and contribute to a more sustainable future. By supporting recycling initiatives, exploring bio-based alternatives, and adopting responsible disposal practices, we can collectively work towards minimizing the environmental impact of 600D nylon and other synthetic materials.