I recently wrote about the thinner nylon fabrics (from 10D to 40D) and how these are often used for weight-critical constructions like tents for backpacking or sports jackets.

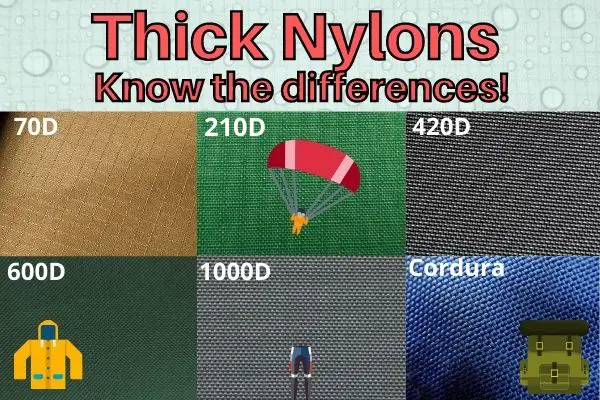

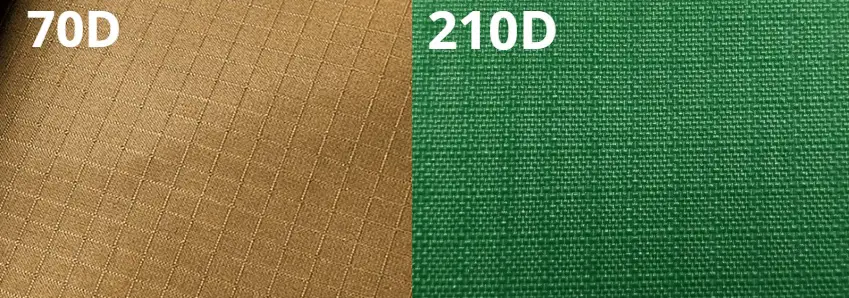

Thicker nylon fabrics like those made from 70D and upwards are sturdy and can be made more waterproof with the right surface treatment. And whereas 70D nylon is often used for tent floors or hammocks, the thicker 210D, 420D, 600D, and 1000D types are strong enough to be used for parachutes, sails, jackets, and backpacks.

Nylon is a synthetic fabric made from the chemical extrusion of polyamides.

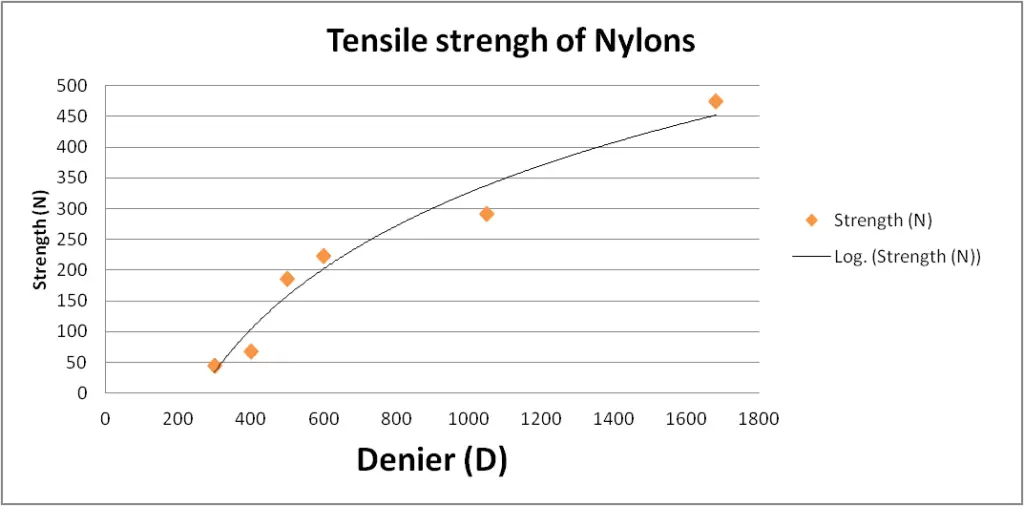

Nylon is one of the strongest synthetic materials and the thicker the nylon thread gets, the stronger the fabric (generally speaking).

Whereas 600D nylon has a tensile strength of around 220N, it takes 475N to break 1680D nylon!

From the graph above you can also see that the strength of nylon increases the most in the beginning, and less when it is already quite thick (high “D” number).

The initial idea with nylon was to make a soft but strong material, which did succeed quite well. In fact, it was originally made as an alternative to silk fabric for clothing, but later it was used in much thicker fabrics as well.

Compared to polyester, nylon is more stretchable and lighter for the same strength. Depending on the coating, it is as waterproof and abrasive resistant, but also more expensive.

Polyester, on the other hand, is often made in thicker versions and is more heat and UV resistant and does not expand when wet.

Most modern nylons are made with the so-called rip-stop technique, which means that strong threads (thicker than the main material) are woven into the fabric at regular intervals.

However, if you are ultra-serious about weight and strength, you should check out the Dyneema (cuben fiber) material!

I am not going too much into the difference between nylon and polyester in this post as you can read all about how those two materials in my other posts on this site.

Nylon is the material of choice for weight-critical products such as ultra-light camping tents. This is because it can be made down to ultrafine threads that allow for the very thin fabric to be made.

Contents

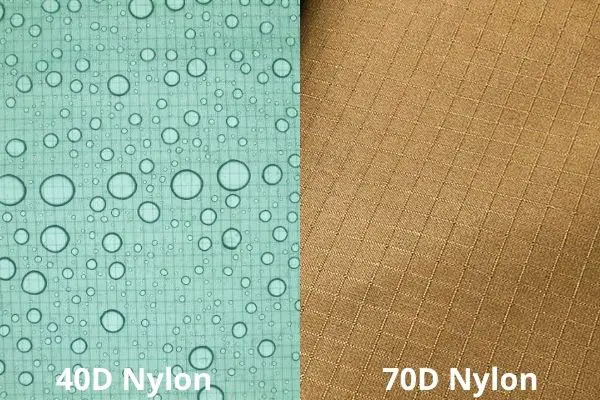

What is the difference between 40D and 70D Nylon?

The difference between 40D and 70D nylon is the thickness of the fabric. 70D nylon is almost twice as thick as 40D nylon and will therefore be stronger and more waterproof, but also heavier!

Whereas the thread used to make 40D nylon weighs 40 grams per 9000 meters (or 4.4 grams per km), the yarn used to make 70D nylon fabric is almost twice as thick at 70 grams per 9000 meters (5.6 miles) of the nylon thread.

The exact weight and water repellent properties of a fabric made with each of these two nylon types depend on the sewing method and final surface treatment applied to make it more waterproof.

70D vs. 210T Nylon

210T nylon is 27 times thicker than and heavier than 70D nylon! Whereas a thread of 70D weighs 7.7 grams per kilometer, 210T fabric weighs 210 grams per kilometer.

People are often confused when the designation says “T” instead of “D”, and sometimes “D” is actually meant, which might be the case here.

If we had to compare 70D with 210D (which is more realistic!) then the thickness of 210D nylon would only be 2.7 times heavier than the thread used to make 70D nylon.

And these fabrics are often used for somewhat strength critical purposes like parachutes, hammocks and rain gear.

What is the difference between 210D and 210T?

The difference between 210D and 210T fabrics is quite large as the thread thickness is 9 times thicker for 210T compared to 210D. Therefore it is important to distinguish “D” (Denier) from “T” (Tex) in fabric designations!

T stands for “Tex” and one T corresponds to the weight in grams of 1000 meters of the thread used to make the fabric as opposed to the 9000 meters used in the Denier designation.

Therefore, Tex measures will generally be thicker than deniers and are often used as designations for thicker fabrics.

It is also important not to confuse Tex with “thread count”, the latter being the density of threads in 1 square inch of the fabric.

100D vs. 210D nylon

100D nylon is made from a fabric thread that is approximately half the thickness compared to the fabric made from 210D nylon.

These two nylon types are both strong and waterproof nylon types that can be used in anything from tents to backpacks and flags.

210D nylon is almost twice as thick as 100D nylon and will therefore be stronger and more waterproof, but also heavier!

Whereas the thread used to make 100D nylon weighs 100 grams (3.5 oz) per 9000 meters (or 11 grams per km), the yarn used to make 210D nylon fabric is almost twice as thick at 210 grams (7.4 oz) per 9000 meters.

The exact weight and water repellent properties of a fabric will depend on the application as some materials of this thickness are treated and others are not. For tents, hammocks and parachutes, a thin layer of silicon is often applied to make the nylon fabric more waterproof.

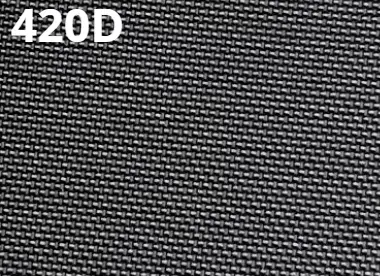

What is 420D nylon?

420D nylon is a thick nylon fabric often used for outdoor gear such as backpacks, medical bags, heavy-duty rain pants and rain jackets.

420D nylon is made from nylon thread that weighs 420 grams (14.8 oz) per 9000 meters (or 4.4 grams per km).

It is also popular as so called Oxford fabrics, mimicking the softness of a dress shirt, but used for waterproof backpacks etc.

It is one of the lightest of the heavier nylon fabrics, but as we will see, this also makes it much more waterproof and resistant to wear and tear!

Is 420D nylon waterproof?

Yes, with the right surface treatment 420D nylon can be made fully waterproof with a >15000mm hydrostatic head.

Even without treatment, if weaved tightly enough, it is thick enough to withstand rain showers, but will dry much more slowly as the fabric will absorb water and expand.

Therefore, you will often find 420D nylon in a version treated with Urethane or some other water repellent material to make it even more water-resistant.

If you are interested in how to waterproof a backpack made from nylon, you might want to have a look at my post on Fjälräven backpacks and how to waterproof them!

Is 420D nylon strong?

The thickness of 420D is ten times that of a sturdy four-season tent that can withstand heavy rain showers and snowstorms.

Nylon is made with strength in mind and with a thickness of 4.4. grams per kilometer, 420D nylon is among the strongest nylon types used for clothing and backpacks.

It will last for many years if used in everyday life, but will also easily last a decade with some rough outdoor use.

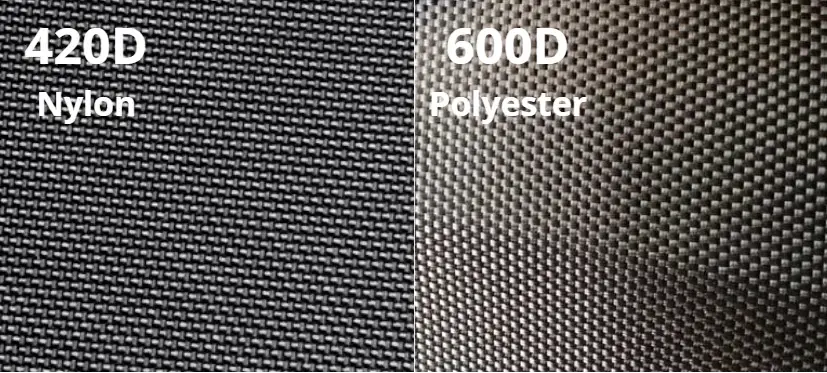

How is 420D Nylon compared to 600D polyester?

The difference between 420D nylon and 600D polyester is not only the thickness, but also the basic chemical composition, and durability of the fabric.

600D polyester is almost 70% thicker than 420D nylon and will therefore be stronger and more waterproof, but also heavier! Polyester is also inherently more fire-resistant and does not absorb water when wet.

Whereas the thread used to make 420D nylon weighs 420 grams (14.8 oz) per 9000 meters (or 4.4 grams per km), the yarn used to make 600D polyester fabric weighs 600 grams (21.2 oz) per 9000 meters.

The exact weight, durability, and water repellent properties of a fabric made with each of these two fabric types depend on the sewing method and final surface treatment applied to make it more waterproof.

However, both 420D and 600D fabrics will be durable and water-resistant in use because of their relatively thick threads, but polyester is quite a lot cheaper!

Do you know the difference between nylon and polyester and that polyester is widely used for rain gear, sleeping bags, tents, and sleeping pads? And do you know how it impacts the functionality?

I wrote an article about the material’s impact on rain gear, on tents, and a post on sleeping pads here.

Take a look at my favorite sleeping bags or check out my post on how to choose an inflatable sleeping pad that is not noisy to sleep on.

Other materials like the extremely durable and waterproof Dyneema material are also used more and more in outdoor gear.

300D vs. 420D Nylon

The difference between 300D and 420D nylon is the level of durability and resistance to wear.

420D nylon fabric generally has a higher level of durability than 300D nylon, meaning it will resist wear and tear better over time.

However, the 300D fabric has a smoother surface due to the thinner threads used, which makes it less likely to snag on things when being worn.

With a tensile strength of around 130N, 420D nylon is much stronger than 300D nylon, which breaks at around 45N, and it will typically also be more water resistant.

This means that 420D nylon can withstand greater levels of stress, making it ideal for things like outdoor clothing and gear.

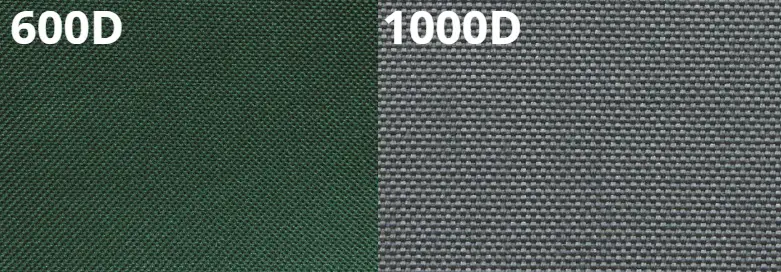

600D nylon vs. 1000D nylon

The difference between 600D and 1000D nylon is the thickness of the fabric. 1000D nylon is almost twice as thick as 600D nylon and will therefore be stronger, more waterproof, and more durable.

However, 1000D will also be heavier than 600D and is used only for the most demanding of fabrics such as military equipment and outdoor backpacks.

Whereas the thread used to make 600D nylon weighs 600 grams per 9000 meters (or 66 grams per km), the yarn used to make 1000D nylon fabric is almost twice as thick at 1000 grams per 9000 meters.

Again, the exact weight and water repellent properties of these fabrics do depend on the sewing method and final surface treatment applied to make it more waterproof.

And although these thick nylon fabrics are very durable in themselves, there are ways to make them tougher.

This extra strength can be achieved via the implementation of other materials with the nylon or innovative ways of interweaving used to create more abrasion-resistant nylon versions such as that of Cordura discussed below.

Is 600D nylon waterproof?

No matter what type (silnylon, ripstop, cordura etc.) a nylon material with a thread thickness of 600D will most certainly be able to withstand substantial water column pressure.

However, the water resistance of 600D nylon, as with all types of nylon and polyester, depends on the tightness of the weave and the surface treatment of the fabric.

A good silicon surface treatment of a tightly weaved 600D nylon fabric will be completely waterproof, whereas a loosely weaved 600D fabric without any surface waterprofing will only be able to withstand temporary waterpreassure of a few thousand millimeters.

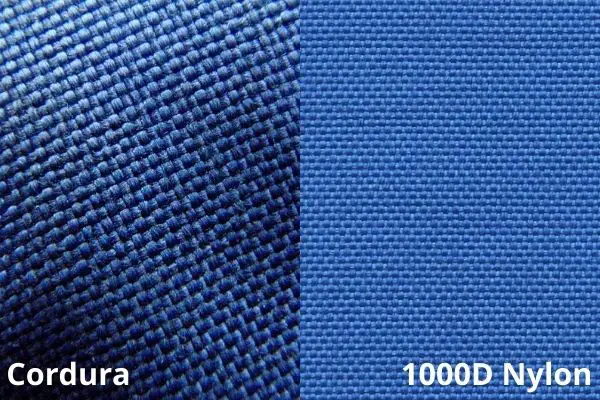

1000D nylon vs. 500D Cordura

Whereas 1000D nylon, also often referred to as ballistic nylon, has a very strong tensile strength, it is less abrasion resistant compared to Cordura or the same thickness.

However, at half the thickness 500D Cordura is expected to be somewhat less durable, but lighter and softer, than 1000D nylon fabric.

Cordura is a nylon fabric that was invented in an attempt to make nylon more wearable and durable. Its fibers are weaved in a way that spreads out the wear and tear more to make it more abrasion resistant compared to normal nylon.

Cordura is sometimes made from not only nylon but also other materials like cotton or Kevlar to make it stronger than regular nylon (a bit like Fjällrävens G-1000 fabric!).

The difference between 1000D nylon and 500D Cordura is not only the weaving but also the thickness of the fabric. 1000D nylon is twice as thick as 500D Cordura and will therefore be stronger, but also heavier!

Whereas the thread used to make 500D Cordura weighs 50 grams (1.8 oz) per 9000 meters (or 5.6 grams per km), the yarn used to make 1000D nylon fabric is almost twice as thick at 100 grams (3.5 oz) per 9000 meters.

However, due to the special fiber structure of Cordura, it will be more resistant to abrasions per weight unit of the fabric.

This is why Cordura is often used, instead of e.g. leather, for motorcycle pants as thick Cordura fabrics can actually resist more impact and abrasion than most other materials of the same softness.

What is the strongest nylon fabric?

The strongest nylon made is ballistic nylon which was used for jumpsuits and flak jackets worn by American pilots during WW2.

Ballistic nylon rangers from 600D to 1680D in thickness are all very durable and strong. The weight of the fabric depends on how tightly it is weaved and often times 1680D is less densely weaved than 680D and is therefore not necessarily heavier!

There are also fusion materials made by blending nylon with other fibers such as kevlar or cotton that are constructed with a specific weaving pattern like Condura to give them higher strength or durability.

However, these types of fabrics are not used for tents as they would be far too heavy and many good alternatives exist at this thickness.

However, nowadays, a cheaper fabric like polyester is also used for many heavy-duty applications as weight is no longer the top priority.

However, if you are really serious about strength but still want a lightweight fabric, you should consider looking into the Dyneema fabric I have recently written about. It is basically the strongest and lightest tent material out there!

Nylon fabric FAQs

To round off, I have included a few more of the most common questions I get about nylon fabric types. These often relate to the use of nylon fabrics used in backpacks or sometimes also used in sleeping matrasses or hammocks.

Which is better, 300D nylon or 400D nylon?

The difference between 300D and 400D nylon is the weight of the fabric. 400D is about 20% lighter than 300D, making it less expensive to produce but not as strong or resistant to water as 300D.

Whereas the thread used to make 300D nylon weighs 30 grams (1.1 oz) per 9000 meters (or 2.7 grams per km), the yarn used to make 400D nylon fabric is almost twice as thick at 60 grams (2.2 oz) per 9000 meters.

The best nylon type for you will depend on what type of nylon will suit your purpose the best. And here, price, weight, and strength should all be considered.

210D nylon vs 600D polyester

Whereas 210D nylon is the weakest of the two, it is also cheaper and lighter. The difference between 210D and 600D is the thickness of the fabric.

The 210D nylon is thinner, but will generally be stronger than polyester for the same thickness so 210D nylon will be comparable to or only slightly weaker than 600D polyester in strength.

210D Nylon is about 1/3 the thickness of 600D polyester and is used for tougher fabrics that are not as water-resistant.

If weight is not critical for you, I would go with 600D polyester as this is cheaper, stronger, and more waterproof.

In general, the pros and cons of nylon vs. polyester apply and you can read all about nylon and polyester in my recent post.

600D nylon vs 600D polyester

The main difference between 600D nylon and 600D polyester is the relative strength, durability, water resistance, and price.

Although they do weigh the same, 600D nylon is stronger than 600D polyester and 600D polyester is generally more waterproof than 600D nylon, but it really depends on the tightness of the fabric weave and the surface waterproofing treatment used.

Another difference between the two is that 600D polyester is generally cheaper than 600D nylon as the nylon is stronger (at least when dry!).

Is 600D better than 210D?

There is no definitive better or worse, but 600D will be quite a lot stronger and more abrasion resistant than 210D if the same basic material and the thread count are considered.

600D will be stronger, but 210D will be lighter and sometimes softer but less water-resistant.

These fabrics are often used as either polyester or nylon in rain gear or by outdoor backpack brands.

References

Synthetic Fibres – Nylon, Polyester, Acrylic, Polyolefin. 2004. Springer Publishing. Editor: J.E. McIntyre ISBN: 9781845690427

THE PROPERTIES AND USES OF NYLON FABRICS. F. Millard. 2009.

Orient Website. The Fabric Strength Challenge.