Ripstop nylon and ripstop polyesters are the most widely used nylon and polyester fabrics used in outdoor clothing, sleeping bags, tents, and hammocks today.

While ripstop nylon is the lightest, most elastic of the two, ripstop polyester is more durable and less expensive.

However, there are several factors that differentiate the two materials, which I will get into here!

Contents

What is Ripstop nylon?

Ripstop nylon is a synthetic fabric made from polyamides. It was originally made to replace soft natural fabrics such as silk. So the initial idea was to make a soft but strong material, which succeeded quite well!

However, today it is commonly used for clothing, tents, sleeping bags, and also for parachutes and hot air balloons due to its lightweight and high strength!

Most modern nylons are made with the so-called rip-stop technique, which means that strong threads (thicker than the main material) are woven into the fabric at regular intervals.

Rip-stop ensures that any tears of the thin main fabric do not propagate along and end up tearing the whole sheet apart.

Compared to polyester, nylon is more stretchable and lighter for the same strength. Depending on the coating, it is as waterproof and abrasive resistant, but also more expensive.

Ripstop polyester, on the other hand, is more heat and UV-resistant and does not expand when wet.

Ripstop nylon is the material of choice for weight-critical products such as ultra-light camping tents. This is because it can be made down to ultrafine threads that allow for the very thin fabric to be made. But thicker versions are also thick enough to make sturdy and waterproof hiking backpacks.

Technically, nylon can be made down to a thickness of 7D, whereas polyester can only be made to a density of 20D (almost three times as heavy!).

But nylon can also be made much thicker for strength and durability up to around 1680D in thread thickness!

Read more about nylon in my recent post about the different types of nylon used for tents.

What is Ripstop polyester?

Ripstop polyester is made from polyethylene terephthalate also known as PET, which is a synthetic polymer. The polyester plastic itself is used for everything from drinking bottles to TV screens and insulation material for your sleeping bag or “down” jacket!

Garments made from thin threads of polyester are mostly used for clothing such as rain gear, furniture, or tents.

Ripstop polyester is suitable for (outdoor) clothing as it is cheap yes strong, resistant to wrinkling, does not discolor in UV/sunlight, and is often regarded as quite rough.

For example, polyester is a major component (mixed with cotton) of the ultra-durable G-1000 fabric from the Fjällräven outdoor brand.

And polyester “wool” is often used as a filling material instead of down for sleeping bags!

When used in outdoor products such as in tents, thicker polyester threads are used because polyester is not as strong as nylon and therefore more polyester material (thicker threads) is needed to obtain the same strength.

In addition, it is simply not technically possible to make polyester threads thinner than a thickness of 20D (whereas nylon can be spun down to 7D!).

This generally makes products with polyester, including tents, heavier than comparable products where nylon is used.

As for ripstop nylon, ripstop polyester comes in different thicknesses that you can read more about here. Some of the thickest polyester types are only used for the groundsheet, backpacks, and raingear.

What do the “D” and “T” stand for in nylon and polyester designations?

The D stands for “Denier” and the T in 210T can stand for “Tex” or “Thread count”.

In most cases the “T” indicates the thread count and says nothing about the thread thickness, but tex and denier do so.

These are all measures of density and are defined as follows:

Denier is the number of grams that 9000 meters of the fabric thread weigh.

Tex is the number of grams 1000 meters of the fabric thread weigh.

Thread count is a measure of the number of threads per square inch of fabric.

So for both nylon and polyester, the fabric density is denoted by a number, followed by the letters D or T.

They all say something about the density of the fabric, but none of these measures are complete!

For example, the yarn used to make 20D nylon weighs 20g per 9km, and the thread used to make 210T, assuming a Tex of 210, nylon weighs 210g per 1km!

However, we get no information about the amounts of threads used for the fabric!

So we might think that 210T corresponds to 1890D by doing the calculation 210*9! Assuming that the same amount of thread is used to make the tent, this would make the 210T polyester (1890/20) 94.5 times heavier than the 20D material!

However, the thickness of 210T material is (approximately 2.5 times) thicker than the 20D so, this would also mean less thread needed to construct the same flysheet.

This is not the case when we compare the weight of two tents made from each fabric (the 210T polyester one is only 15% heavier than the 20D nylon version…).

So, here 210T must refer to the thread count, which means that 210 threads are used per square inch. For this amount of threads to fit into one square inch at a 15% extra weight, the thread thickness will have to be around 68-75D (denier) of thickness.

So 210T is actually more like 70D that we can compare to the 20D of the nylon.

In this case, which is often the case for polyester, the “T” rather stands for thread count meaning the number of polyester threads per square inch of fabric. So no say about the density of the thread used, but in these fabrics, the density is usually around 70D for polyester of this type.

See my recent post on different nylon types for an overview of the weight and water resistance of the different nylon types!

The density is also sometimes expressed in decitex (dtex), which is the weight in grams of 10 kilometers of fiber instead of the 9 kilometers used for Denier.

Some tent models allow you to choose between nylon and polyester.

For example, those of the Naturehike Cloud up or Opalus series tents (see more in my blog post on cheap tents), where one can choose between 20D nylon and 210T polyester. You can see how the choice of material influences the weight!

That’s almost one pound (0.7) weight difference from 20D Nylon to 210T Polyester for the same tent!

How much water can ripstop nylon and ripstop polyester withstand?

Ripstop nylon and ripstop polyesters are both water resistant, however, the nylon is lighter and more waterproof as it can typically withstand a higher water column pressure compared to polyester for the same thickness.

The flysheet of a tent is often made out of either ripstop nylon or ripstop polyester, so it is important that water does not leak through.

For example, 20D Ripstop nylon is rated to 4000mm whereas 210T ripstop polyester can only resist 3000mm water pressure despite it being quite a lot thicker!

A marked downside of ripstop nylon is that it expands when it gets wet! Ripstop nylon may expand as much as 3.5% when soaked whereas polyester does not expand or gain weight when it rains.

This property of nylon may explain why tents made of nylon will sack more after the rain compared to a tent made from polyester.

However, because nylon is often thinner and more breathable, nylon will dry more quickly compared to polyester, which is nice when used for raingear.

Producers of nylon tents will often try to prevent the water from being absorbed by the fabric in the first place by treating the nylon fabric with a water-repellant such as silicone or DWR.

These treatments will work best at the beginning of the tent’s lifespan, but will slowly wear down due to wear and tear – including the UV rays of the sun!

Does Ripstop nylon or Ripstop polyester Tent Dry Faster?

How long the fabric takes to dry is a very important consideration when choosing the fly sheet material for a tent if you want to avoid having a wet moldy tent laying all day in your backpack!

Because polyester does not absorb the same amount of water when exposed to rain as nylon does, it will also dry faster.

Whereas it takes a nylon tent around four to six hours to dry under dry conditions, it takes a polyester tent more like three hours to dry completely after a heavy rain shower!

This is because nylon keeps the water embedded in between its thread fibers, whereas polyester repels it more easily which helps it dry faster.

Is ripstop nylon or ripstop polyester the strongest?

Other aspects worth mentioning are the strength and flexibility of the materials. Ripstop nylon is generally stronger than ripstop polyester. It is also much more flexible and will stretch more before any damage is done.

But it also depends on the thickness of the threads used for the ripstop! Thicker ripstop threads will make the fabric heavier but stronger.

See my recent posts on some of the strongest nylons and how strength is measured!

However, it may tear more easily when the damage is done. While nylon is strongest when it comes to sudden pulls and tears, polyester is generally more resistant to pilling and UV damage, so you will see fewer of those annoying threads sticking out in an old polyester tent.

Why is ripstop nylon more expensive than ripstop polyester?

Because the production of nylon is more time and energy-intensive, nylon is the more costly of the two materials.

Both are made in a process of spinning out a polymer after reacting two chemicals, however, polyester does not require the same amount of processing and heating as nylon does.

The nylon fabric is usually also made via thinner threads, which demands more from the extrusion and spinning process than what is needed for polyester.

Both nylon and polyester can be made via recycled materials, however, it is much more expensive to reuse nylon.

Ripstop polyester can be made almost directly from reused bottles whereas nylon is more complicated and can be made from fewer materials such as old fishing nets.

Chemical facts about nylon and polyester

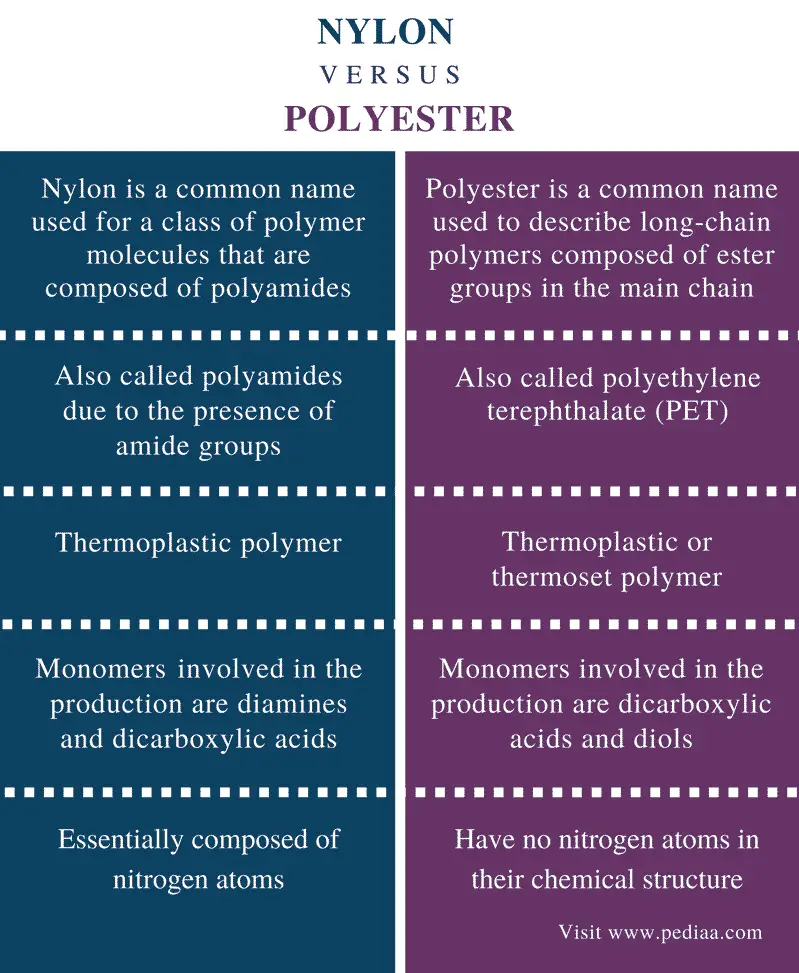

Chemically speaking, nylon and polyester are similar only in the sense that they are made up of polymers derived from dicarboxylic acids. Ripstop nylon contains amides in its structure, whereas polyester, as the name suggests, is a long chain of esters.

This composition makes nylon inherently more hydrophilic and therefore less waterproof and harder to color.

Does nylon or polyester burn more easily?

Well, both materials are synthetic plastics so they do catch fire or melt when subjected to a naked flame. However, the melting temperature rating of nylon is 220 degrees Celsius (428 F) whereas polyester melts 40 centigrade higher at 260 (500 F), which leaves polyester as the winner here.

The ripstop threads incorporated into the nylon or polyester, do not significantly influence the melting of flaming

Bot materials can be produced with or treated with flame-retardant chemicals. Heat-resistant nylon can be brought up to the same temperature as polyester at around 255 C (491F) whereas polyester may be treated with flame retardants to withstand up to 440 C (824F).

Another difference in behavior between nylon and polyester when subjected to fire is, that nylon will mostly melt completely before catching fire whereas polyester will catch fire more quickly and melt simultaneously.

Is ripstop nylon or ripstop polyester better?

If you are considering buying a tent, backpack or clothing item made from nylon instead of a similar item made from polyester, there are a few reasons to do so.

The most appealing one is the weight and feel of the fabric. Ripstop nylon is generally softer and more silk-like than polyester, which can seem a bit rougher in its texture. Ripstop nylon is also more compact, which makes it easier to pack down.

However, for the thicker nylon version from 70D and up, this quality is not as pronounced as they are quite hard and sturdy and are also applied as such (an not for the soft feel…).

Advantages of ripstop polyester vs. ripstop nylon:

- Cheaper than ripstop nylon

- More abrasion resistant

- Fast drying, low moisture absorbency

- No sagging when wet

- No loss of strength when wet

- Resists chemicals and dyes

- Resistant to UV light

- More resistant to heat

- Less static and pilling

- Less prone to shrinkage and wrinkles

Disadvantages of ripstop polyester

- Ripstop polyester is heavier than nylon for the same strength

- The tensile strength of polyester is approximately half that of nylon

- Ripstop polyester is harder to wash

- Harder to color and dye

- Catches fire rather than melting

In summary, you should go for nylon only if weight, strength and the ability to be dyed and compacted means something to you!

Conclusions

The main difference in materials when it comes to tents is in the sheet material and the tent poles.

Whereas the overall functionality and weight properties of a tent are determined by multiple parts of the tent e.g. the tent poles, the flysheet, the inner cabin, and the floor make up >80% of the total tent mass.

While there are numerous similarities between nylon and polyester, they do have their crucial differences that are important to consider for tents and other outdoor applications such as rain gear and also lightweight hiking backpacks.

Because nylon is slightly more technically difficult to make in the quality needed for tents, nylon tents are also slightly more expensive.

For the ultralight backpacker, nylon is the obvious choice whereas the festival fanatic or occasional car camper will be better off with a cheaper polyester tent. I have written about my favorite lightweight tents made from nylon or polyester here!

And there is of course more to a good camping trip. I just made a list of some of my favorite budget hiking gear including everything you need for a good night’s sleep in a tent.

For more information on materials and backpacks from different brands, check my posts on Fjällrävens innovative material use, and how it compares to other outdoor brands like The North Face and Osprey.

Ripstop nylon vs. Ripstop polyester FAQs

In this section, I will answer some of the most common questions about the difference between different types of nylon and polyester.

Is 40D ripstop nylon waterproof?

Per default, 40D nylon is not waterproof but only water-resistant. However, silicon spray can be applied to give it a waterproof rating of up to 5000mm hydrostatic pressure.

Is ripstop nylon UV resistant?

Nylon is not as UV resistant as other synthetic materials such as polyester that is also used for tents and backpacks.

Depending on the application, nylon will do fine in sunlight but a backpack or tent made from ripstop nylon will lose color and strength with time if exposed repeatedly to strong sunlight.

What is the difference between 20D ripstop nylon and 75D ripstop polyester?

The main point here is that 20D ripstop nylon is thinner and lighter than 75D ripstop polyester. A 20D thread weighs 20 grams per 9000 meters whereas a 75D thread weighs 75 grams per 9000 meters of thread.

The untreated fabric made from 20D nylon typically weighs less than 1 oz/sq. yard whereas 75D polyester weighs around 2 oz per sqare yard.

Whereas 20D is a good tent fabric, 75D polyester is more often used in clothing items.

75D polyester vs 40D nylon

The 40D nylon uses twice as thick a thread as that of 20D and almost half the thickness of 75D polyester.

40D nylon fabric, however is not twice as strong as 75D polyester, but it is one one the thickest fabrics used for tents. Whereas 40D is often used for the floor of lightweight tents, 75D is rarely used for tents is more often used for clothing and flags.

You can read more about 40D nylon here.

What is the difference between 40D ripstop nylon vs. 70D ripstop polyester?

70D polyester thread is almost twice as thick as a 40D nylon thread. 40D nylon thread weighs 40g per 9 km and 70D polyester weighs 70 grams per 9 km.

These fabrics are a bit too thick for most lightweight tent flysheets, but may be used for tarps, rain jackets, ponchos and sleeping pads. The 70D polyester is the preferred choice for applications where water resistance is key.

420 Denier ripstop nylon vs 600 Denier ripstop polyester

The thickness of 600D (denier) polyester is about 1.5 times that of 420D nylon. The fabrics woven from these types of threads are very thick and are often used for durable clothing or backpacks.

600D polyester will generally be more abrasion resistant and waterproof than 420D, but will also weigh more.

I wrote a whole article about 600D polyester if you are more interested in thick polyesters.

You can read more about the thicker nylons including 420D and 600D in my latest post.

Did you know that nylon and polyester is widely used for rain gear, sleeping bags and sleeping pads? And do you know how it impacts the functionality? I wrote an article about the material’s impact on raingear performance here.

Take a look at my favorite sleeping bags or check out if nylon backpacks are waterproof, and how the material can make an inflatable sleeping pad noisy to sleep on?

Other materials like the extremely durable and waterproof Dyneema material are also used more and more in outdoor gear.

References

https://www.nature.com/articles/pj200747.pdf?origin=ppub

https://www.sciencedirect.com/science/article/pii/S1110062115200785

www.pediaa.com